Another unique custom design created by CCI for a unique manufacturing process. For this project the customer needed a process tray to move the product throughout the facility but needed the handles to extend above the unit so the trays could be placed on a lower cart without the operators fingers getting trapped underneath the tray.

Category: Uncategorized

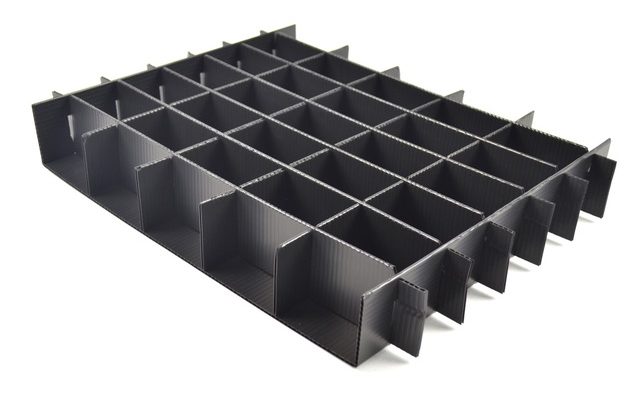

Sealed Edge CFP Straight Up Partitions

Straight up partitions are very economical as it uses half the raw material used in a bent over style. CFP (Conductive fluted plastic) partitions have a sharp edge when designed as a straight up set. It works okay especially if the product extends past the top of the partition set, but CCI now offers an alternative.

Alternative To Bubble Wrapping Boards

A common way to protect circuit boards or assemblies has always been to wrap each board with pink bubble wrap. We recently created an alternative solution that eliminates the pink “short term ESD” bubble wrap and its waste, the excessive handling needed to “wrap” around the board and fasten with tape and the excessive handling needed to unwrap the board. The excessive handling in that scenario creates an opportunity to damage the board both physically and electrically. Remember, the standard rule of thumb in electronics manufacturing is that every time you handle a product you introduce the opportunity to damage the product both physically and electrically (ESD damage). By eliminating a lot of the excessive handling it eliminates a lot of that damage. Handle less – damage less.

High Tech Packaging Solution For High Tech Product

Custom Manufacturing – Kitting Solution

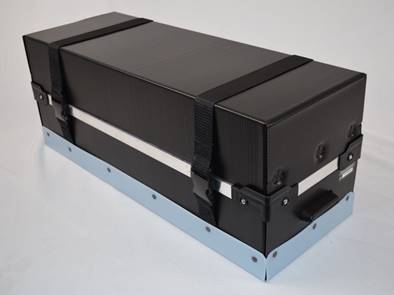

Custom ESD Protective Case For High Value Product

This highly engineered custom protective case keeps the high value product secure during manufacturing, transport and storage.

The Durastat style container with large reverse lid made out of conductive fluted plastic provide a strong outer shell. Inside is contoured ESD safe foam that cradles the product as it rests in the container. Once the lid is placed on the tote strong straps with snap together buckles secure it in place. To finish the design we have affixed S680 plastic to the bottom so the container easily slides on and off racking and carts. All materials are permanently ESD safe and specifically chosen to fit the application.

Kleanstat Bubble Rolls: Permanent ESD Protection & Inherently Static Dissipative

Industry-leading, KleanStat Flex Bubble is now available in roll stock! Use the rolls to line workstations, wrap delicate components, or any other FOD Free, anti-skid application. All rolls are available in fifty foot (50LF below) sections and come ready to cut to desired lengths. Rolls can be ordered in custom lengths, please call for more information.

KleanStat Flex TPU:

- Permanent 10e9 range static dissipative

- Best flexibility and memory

- IPA cleanable

- Highest clarity

- Great cleanroom material

- Extremely tough (will not tear)

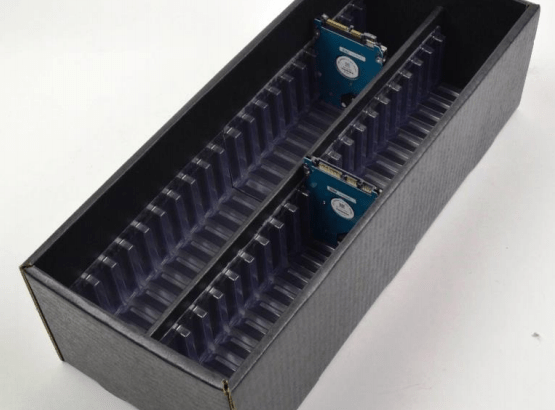

Plastic Ribbing: Economical, Clean & Easy to Use

CCI has many standard plastic ribs that we can use to line a tote. As long as there is enough “real estate” on the edge of the board it is a great way to eliminate the rubbing of boards against a hard divider and makes loading and unloading easy and efficient. Turned on its side, the operators will find the versatility of being able to position it at their workstation a huge plus.

Solutions for Fragile LED Boards

LED boards are very fragile and extremely sensitive to physical and ESD damage. Careful handling is important to maintain the integrity of the product.

By using thermoforming, you can achieve many objectives:

Clean – No FOD Solution

Physical Protection

ESD Protection

Maximize space

Ease of Handling

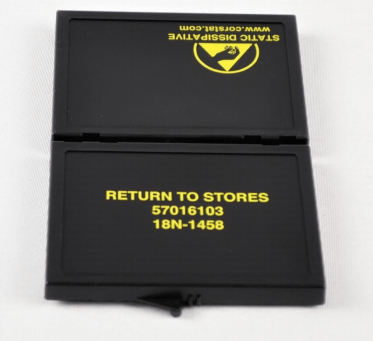

Hot Stamping ESD Injection Molded Cases

CCI has a wide selection of injection molded cases. CCI’s case design features sturdy hinges and snap closure. Each half of the container is designed to overlap to eliminate any gap where the two sides come together.