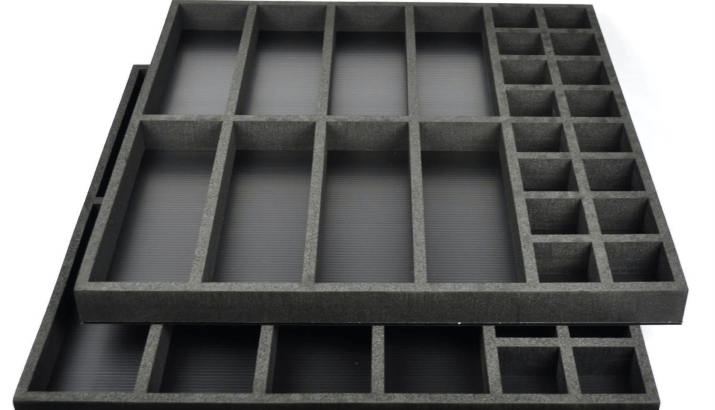

Foam isn’t always used just for cushioning. We can create a “softer” partition wall when that is required. Here we have created a unique “kitting” stackable tray using foam to create the cavities. The foam is laminated to CFP. The cavities are deep enough so that when loaded with product the trays can be stacked. Another unique design by CCI.

Category: Uncategorized

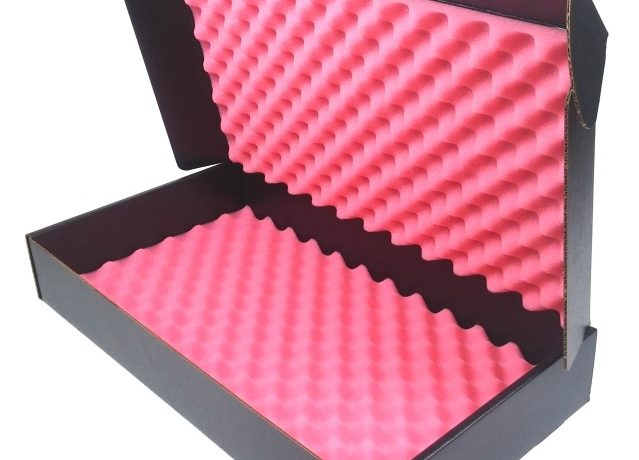

Foam Ribbing Shipper Option

This is an economical one-way shipper that provides great cushioning and a Faraday cage. The design utilizes pink foam ribbing strips to securely hold the boards in place. A soft pink foam on the bottom and attached to the lid give extra cushioning during transport. The use of pink foam makes this a short-term use container. By switching the pink foam with black permanent dissipative foam, it now turns into a long term returnable/reusable solution.

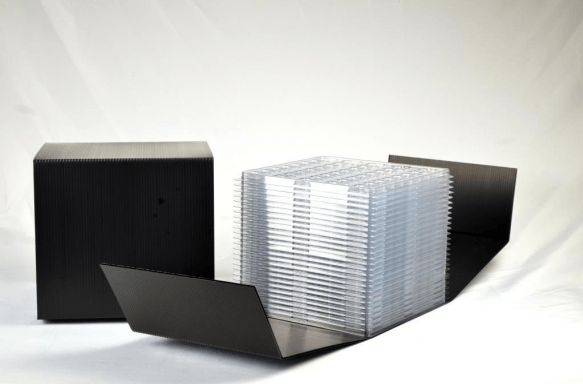

ESD Tray Stacks

Using thermoformed trays in a returnable/reusable system is very common. Trays provide the best physical and electrical (ESD) protection. Once the tray is designed there are many ways to pack in multiples for shipment. Considering handling requirements on both ends we design a system that helps to eliminate as much handling as possible, fit within the parameters of manufacturing and shipping and is operator friendly.

Corstat Dividable Tray

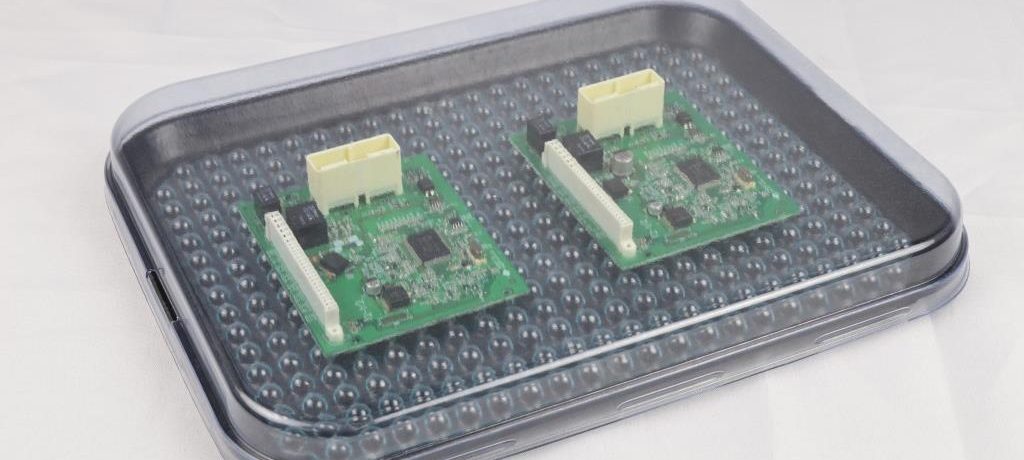

A less expensive design option for a dividable process tray made out of Corstat and utilizing Kleanstat Flex bubble. This tray is stackable and by using both bubble and physical dividers it insures that the product is separated during the handling process. When the trays are stacked you create a Faraday Cage for shielding. Some great additions to this would be a document holder on the side, a full telescoping cover for storage or any other add on that would best fit your handling processes.

The Cleanest, FOD Free, Cleanable, Solid Box, and ESD Cleanroom Safe Case

A clean FOD Free package created to: Protect the product from dust and debris, Create a Faraday Cage, and Be acceptable in a clean room environment.

Customize Your Existing Totes To Create A System That Fits Your Specific Needs

If you have already invested in containers and they don’t quite fit your needs we can customize the interior to make them efficient. Thermo-formed trays are a great way to protect your product physically, maximize the number of units per tote, have a clean FOD free system and increase your ESD protection. Dividers designed specifically to you product size helps to maximize space and is a low cost alternative to existing configurations that might not work as well as you like. Die cut foam provides great cushioning and can be done in multiple configurations.

Getting a Handle on Handles

CCI Custom Manufacturing

The ability to do custom manufacturing specific to an application opens up a whole new world of possibilities. CCI is an extension of your engineering mind. How many times do people settle for an “off the shelf” solution and then try to conform to the limitations of the product? With CCI’s custom manufacturing capabilities why not look at designing a container based on your needs instead of designing your manufacturing based on the containers needs and limitations. One of CCI’s custom manufacturing items is a kitting container that was designed specifically to fit into the existing manufacturing environment without having to make “adjustments”. In fact it actually improved the process which was the original goal.

Eliminate the “Electric Slide”

Is Pink Foam Helping or Hurting Your ESD Compliance Program?

History

Pink ESD foam has been a staple in the ESD packaging world since its inception back in the 70’s. It is a great product that fulfills many needs in many applications. Typically used as a cushioning aspect of a package or work surface, pink foam has been a “solution” for many problems. However, there has been a misconception of the anti-static properties and how long they last. Pink anti static foams have a shelf life. Once that shelf life is gone the foam can become extremely dangerous to the manufacturing environment and sensitive components. When walking through an EPA (ESD Protected Area) the most common violation of standard ESD practices is the use, or misuse of these foams.

ANSI/ESD S541 tells us in 6.1 and 6.2 as it relates to ANSI/ESD S20.20 that packaging (in this case pink foam) used inside and outside an EPA must have certain characteristics.