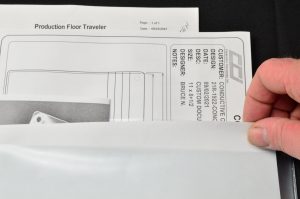

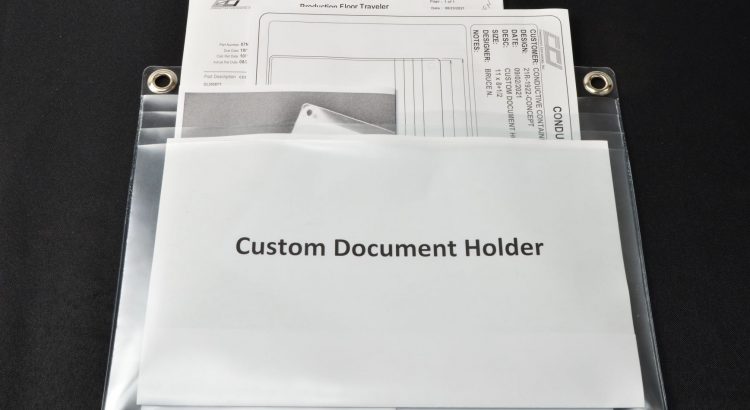

We have created a unique document holder that separates paperwork during use. Made from our superior KleanStat Flex™, the document holder features four pouches. Each pouch will hold a 8 1/2 x 11 document. The holder has two grommets on the top for use in either hanging or attaching the holder to the totes. KleanStat Flex™ is permanently static dissipative and can be cleaned with IPA without denigrating the ESD properties. Manufactured using RF welding the pouch is tough, durable and gives the user great flexibility in sorting the documentation as it moves through the manufacturing process.